A heat sealer is a machine used to seal products, packaging, and other thermoplastic materials using heat. This can be with uniform thermoplastic mono layers or with materials having several layers, at least one being thermoplastic. Heat sealing can join two similar materials together or can join dissimilar materials, one of which has a thermoplastic layer.

SEALING MACHINES

-

Hand Operated sealers

-

Foot Sealers

-

Continuous Sealers

-

Induction Sealers

-

Foil Sealers

HAND OPERATED SEALERS

-

HB Size 8″, 12″, 16″, 20″

- Used to seal light gauge PE/ PP pouches.

-

HH Size 8″, 12″, 16″

- Used to seal High gauge PE/PP/ All kind of laminated pouches.

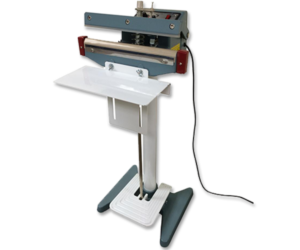

FOOT SEALERS

-

FE Size 8″, 12″, 16″, 20″, 24″

- Used to seal light gauge polythene pouches.

-

FH Size 8″, 12″, 16″

- Used to seal High gauge PE/PP/ All kind of laminated pouches.

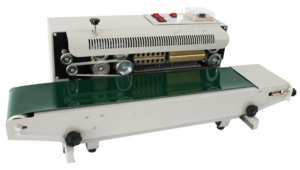

CONTINUOUS SEALERS

Band Sealer(Horizontal)

Horizontal band sealers are used to perform equipment that is cost effective and known for its high performance. The sealer has a PVC conveyor belt of width 200 millimetres that is capable of carrying weight of up to 3 kilograms.

Band Sealer(Vertical)

The band sealer is an automated form of a heat sealer with a conveyor belt. Driven by a motor controlled by a speed regulator, bags of unpacked material are funneled into a teflon heating element which seals the ends of each bag via thermoplastic melting.

INDUCTION SEALERS

1. Manual induction sealing machine

Model 120 P

2. semi automatic

Good for sealing with wads for chemicals and pharmaceutical products.

FOIL SEALERS

The machine is a manually operated machine. It is used for sealing the mouth of the different containers using aluminum foil sheet. This machine seals the containers by heat seal method.