SEALING MACHINES

A heat sealer is a machine used to seal products, packaging, and other thermoplastic materials using heat. This can be with uniform thermoplastic mono layers or with materials having several layers, at least one being thermoplastic.

Engineered for Flexibility, Low Maintenance and High Operation Speed, our pouch packaging machines are renowned for delivering consistent product quality. These packaging machines are tailor-made to meet the specifications of our customers.

A heat sealer is a machine used to seal products, packaging, and other thermoplastic materials using heat. This can be with uniform thermoplastic mono layers or with materials having several layers, at least one being thermoplastic.

This includes Horizontal Flow Wrap Machine, Bag Closers, Hand Operated Coding Machines, Cream/Paste filling machines, Vacuum Packaging machines, Strapping machine, Conveyors, etc.

A vertical form fill sealing machine is a type of automated assembly-line product packaging system, commonly used in the packaging industry for food, and a wide variety of other products.

Auger filler, which is used to fill accurate weight size of powder in bottles, pouches. Auger filler is powder filling equipment which can be set to fill various types of powder. Powder filling is automatic filling machine runs of volumetric filling principle.

The shrink wrap machine sealer is used to close open ends of the shrink film and the heat source applies heat to the film to shrink it down to the product being wrapped. Low output operations often use a heat gun as the heat source.

Labeling machines are machines that dispense, apply or print-and-apply labels to various items, products, containers, or packages. One of the most popular types of labeling machinery is the automatic labeling machine, which is able to do its job without needing an operator.

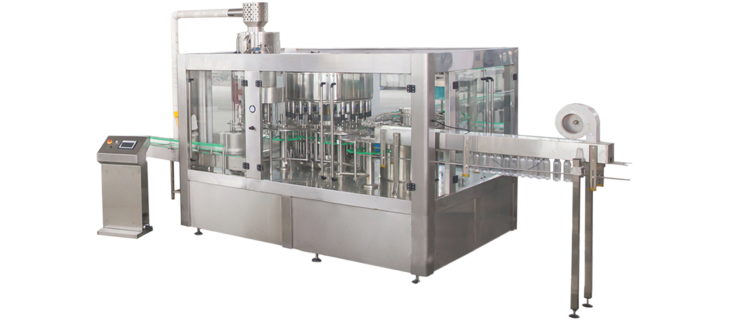

Fully automatic process like Bottle Rinsing, Filling, Capping Machine etc. This machine equipped with man-machine technology with all automation. Mainly used for washing, filling and capping, etc. Ranging from : 2400 BPH – 18,000 BPH.

Coffee production is the industrial process of converting the raw fruit of the coffee plant into the finished coffee. The coffee cherry has the fruit or pulp removed leaving the seed or bean which is then dried.

Top quality ink specially formulated for printing on Glazed/Non Glazed,Metallic/ Non-Metallic surfaces,Art,Wax, Plastic Varnished Coated Paper, PVC containers.

Vacuum packing is a method of packaging that removes air from the package prior to sealing. This method involves (manually or automatically) placing items in a plastic film package, removing air from inside, and sealing the package.

Paste Fillers: Paste fillers use a volumetric method for measuring and controlling the filling quantity of the pastes. This efficient method is easy to maintain and particularly handy for highly viscous products. At the base of this machine is a self-priming cylinder where a piston can easily move.

Tea processing is the method in which the leaves from the tea plant Camellia sinensis are transformed into the dried leaves for brewing tea. In its most general form, tea processing involves different manners and degree of oxidation of the leaves, stopping the oxidation, forming the tea and drying it.

P.O BOX 1980-00606

Office No. A8 Hillocks Country Club Enterprise Rd. Nairobi Kenya.

+254703777999, +254202210123

excelpealtd@gmail.com, info@excelpea.co.ke